Meaningful contributions which shape the future: Intermas and the Wind Energy Industry

Related News

Llinars del Vallés

NOT TRADE FAIRS

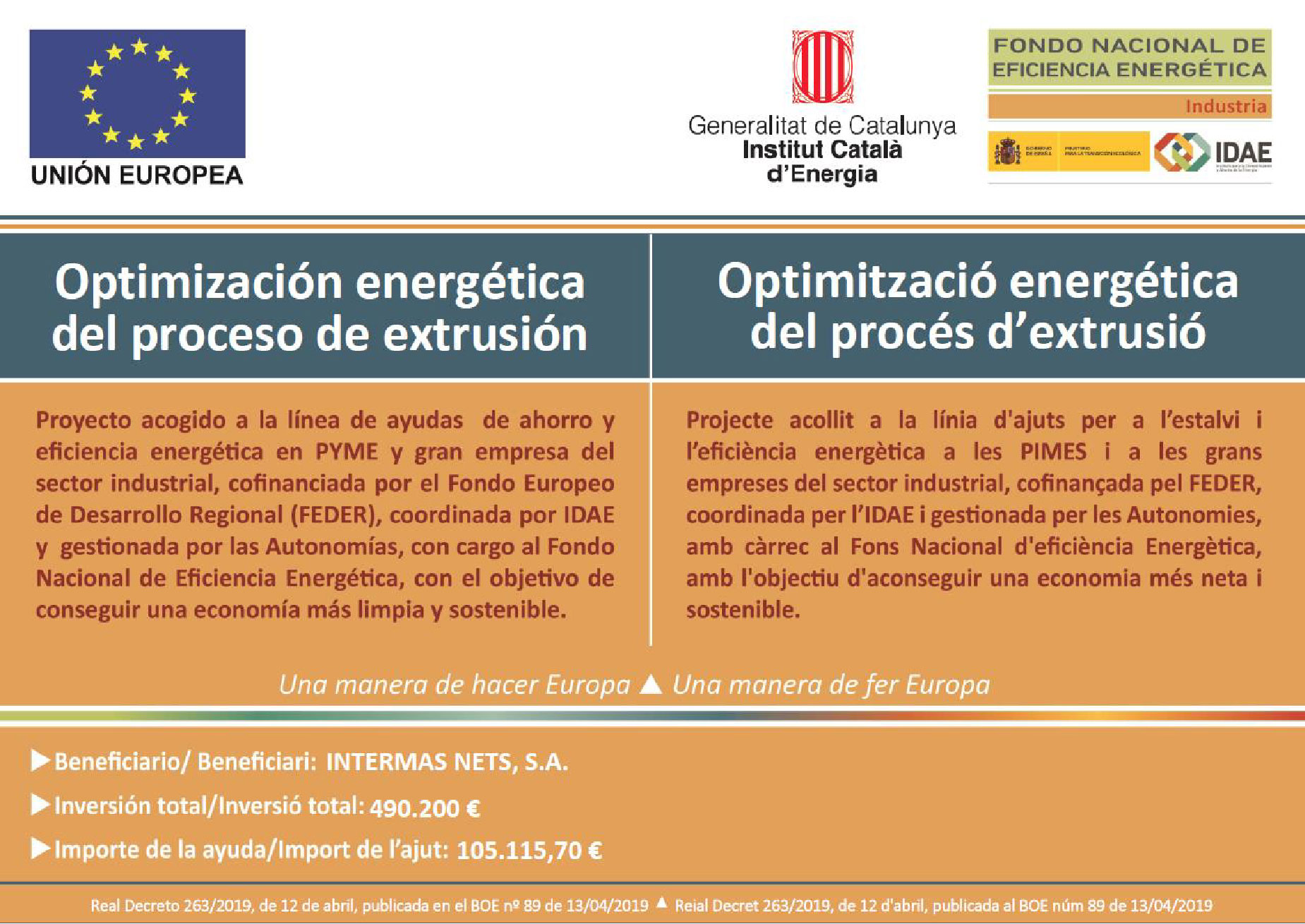

Optimización energética del proceso de extrusión

INTERMAS NETS, SA ha recibido una ayuda para su proyecto de ahorro y eficiencia energética “Optimización energética del proceso de extrusión”,...

NOT TRADE FAIRS

Ahorro y eficiencia energética en los sistemas de alumbrado

INTERMAS NETS, S.A. ha recibido una ayuda para su proyecto de ahorro y eficiencia energética MEJORA SISTEMA ALUMBRADO NAVE 1 Y NAVE 108 cofinanciada...

France

NOT TRADE FAIRS

Demonstrations of detection of our warning mesh equipped with ELIOT technology (GA ELIOT), last September.

During these 2 demos, we carried out the following operations: detection of RFID chips with depth test, and GPS signal. Rewrite closed dig chips using...

26 Oct 2022 - 27 Oct 2022

Bizkaia Aretoa (Bilbao)

NOT TRADE FAIRS

Intermas Geosynthetics participates in the VII Congress Versos 2022 in Bilbao

The VII Congress on the best available technologies in landfills, contaminated soils and waste management, VERSOS22, will be held on October 26 and 27...

08 Jun 2022

Barcelona

NOT TRADE FAIRS

Econocom Nexica recognises Intermas with the Innovation Award 2022

The continuous technological evolution has become a key factor for the development of companies.

Along these lines, Intermas Nets (or Intermas) has...

Celloplast, Val-du-Maine - France

NOT TRADE FAIRS

Index de l’égalité professionnelle de Celloplast 2022 au titre de l’année 2021

Dans le cadre de la loi pour « La liberté de choisir son avenir professionnel », Celloplast publie ses résultats à l’index d’égalité femmes/hommes.

NOT TRADE FAIRS

Biodiversity World Day, Oysters a key species

Oysters are a key species, as they play a fundamental role in maintaining biodiversity in the ecosystem and in the cycle and cleaning of water....

Flé, département 21 - France

NOT TRADE FAIRS

ELIOT “DRINKING WATER” WARNING FENCE DETECTION OPERATION WITHIN SESAM 21

As part of work to renew the drinking water pipeline in the town of Flée (21), Intermas intervened on the site during a detection demonstration with...

NOT TRADE FAIRS

intermas extruded nets reused for a Carnival ecofriendly float.

Celebrating Carnival in creativity sustainable way thanks to the reuse of Intermas extruded nets.

NOT TRADE FAIRS

INTERMAS HAS BEEN AWARDED WITH ECOVADIS GOLD MEDAL.

We are very proud to announce that Intermas has been awarded with the Gold Medal of EcoVadis for its sustainability development. This medal places the...

Interconnection between Vinay and Monthelon (France, dpt 51)

NOT TRADE FAIRS

New Worksite with Intermas Warning Grilles equipped with Eliot technologies

As part of rehabilitation work on the drinking water network, and the creation of a link between Vaudancourt and Vinay (dpt 51, France), Intermas...

NOT TRADE FAIRS

Intermas Aquaculture and its contribution to Blue Carbon to combat climate change

Intermas Aquaculture is committed to offering solutions for the cultivation of algae, specifically the Kappahycus and Gracilaria sp. These solutions...

NOT TRADE FAIRS

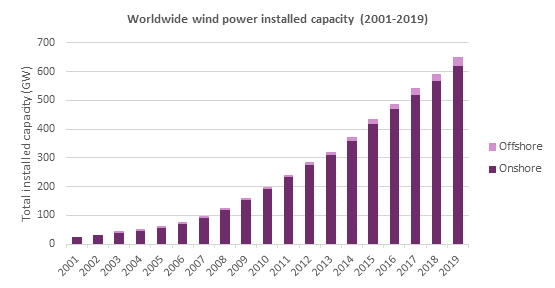

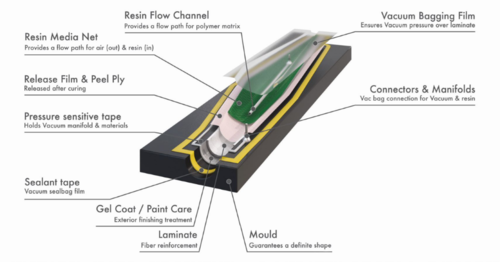

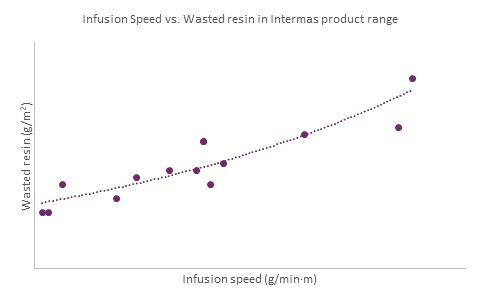

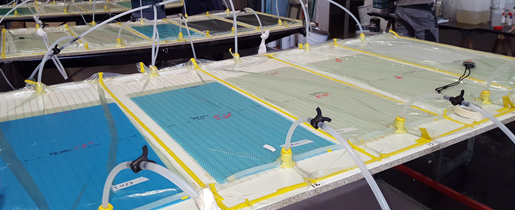

Recyclability is one of the keys for the sustainable future of the wind blade manufacturing industry.

In Intermas we manufacture netting with 100% recyclable polymers targeting the most demanding industries

28 Feb 2022

NOT TRADE FAIRS

New advanced and affordable oyster growing multisystem: Oyster Basket AP8

Intermas Aquaculture proudly present you a new product for oyster growing.

NOT TRADE FAIRS

Oyster bags offers many advantages and benefits to grow Oysters

DID YOU KNOW...?

Growing Oysters helps protect the environment, in addition to providing us with a very nutritious food.

23 Nov 2021 - 23 Nov 2021

NOT TRADE FAIRS

Recruitment campaign on our French site Celloplast

For our fourth year of partnership with Pôle Emploi, last Tuesday we received 25 job seekers.

Intermas

NOT TRADE FAIRS

Intermas: experts in high-temperature netting for the filtration industry

The increased global demand for cleaner air and liquids leads to new challenges for the filtration industry. Today, a broad range of industrial...

NOT TRADE FAIRS

Preserving biodiversity with AGROSOL mulch fabrics for green space plantations and market gardening

Greater risk prevention is currently considered in terms of preserving the environment both in agriculture and in public communities. It is necessary...

Hungary

NOT TRADE FAIRS

INTERMAS EASTERN EUROPE, has won this year the prestigious BUSINESS SUPERBRANDS award.

We are pleased and proud to inform all our our Partners that INTERMAS EASTERN EUROPE, as the exclusive Hungarian distributor of NORTENE brand, has won...

France

NOT TRADE FAIRS

Construction site with ELIOT equipped warning meshes (GA ELIOT)

AEP network. Interconnection between Château-Thierry - Fère en Tardenois (France, dpt 02). Visit on the section passing through the town of Epieds.

NOT TRADE FAIRS

One-on-one with netting: Types and industrial applications

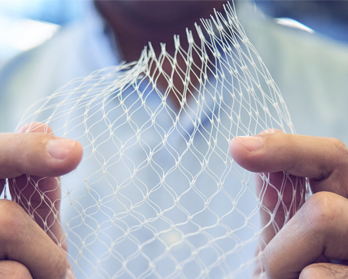

Extruded netting is amongst those things that are involved in our everyday life and yet remains a great unknown. Meshes are used in the most demanding...

Delta del Ebro

NOT TRADE FAIRS

Business collaboration between the Vocational Training & Intermas Aquaculture

Biocomposable products used in the cultivation of bivalves are tested in the Ebro Delta.

10 May 2021

Intermas

NOT TRADE FAIRS

Are you familiar with Intermas BOP meshes?

BOP stands for Bi-Oriented Polypropylene. Orientation is an advanced manufacturing technology that confers plastic netting with very unique technical...

06 Apr 2021

Germany

NOT TRADE FAIRS

Cost-effective ventilation solutions

Check out a great example of creative and meaningful applications of Intermas extruded netting.

59 Nord, France

NOT TRADE FAIRS

Filets de Sols Pollués (FSP)

Nature du chantier : chantier de dépollution sur le site de Courcelles-Lès-Lens (62) – décembre 2020

NOT TRADE FAIRS

SAFE TUBE becomes INTERSAFE

Nothing change, just the name! An open tube, very resistant, quick to install, reusable and all at a very competitive price.

Intermas nets

NOT TRADE FAIRS

GREEN LABEL CERTIFICATE OF APPRECIATION

Intermas Nets has been awarded by the PRS Green Label 2020!

Intermas

NOT TRADE FAIRS

Challenge accepted ! We customize your mesh!

With over 60 years of production experience, at Intermas we work always closely with our industrial customers. By understanding our customers’ needs,...

NOT TRADE FAIRS

Intermas Biorope as an alternative to synthetic mooring lines

Do you want to know more about our biodegradable and compostable rope in development? Boat Industry magazine talks about our moorings solution which...

27 Oct 2020

NOT TRADE FAIRS

Performance of high-quality drainage geocomposites and analysis of the carbon footprint vs. conventional solutions

Do not miss our technical session presented by our engineer Sergi Conesa on October, 27th (6pm – 7.30pm UTC+1) and on October, 31st (6pm – 7.30pm...

Château-Thierry – Villers Cotterets (France, 02)

NOT TRADE FAIRS

Jobsite reference with warning mesh equipped ELIOT technology (GA ELIOT)

Water supply connexion between Château-Thierry – Villers Cotterets (France, 02)

NOT TRADE FAIRS

Intermas leads the way by changing industrial packaging habits

Discover our new range of biocompostable nets.

26 Oct 2020 - 31 Oct 2020

Rio de Janeiro, Brazil

NOT TRADE FAIRS

Intermas Geosynthetics Teams at Online GeoAmericas Conference

GeoAmericas comes to Brazil in its 4th edition, which will be held in October from 26th-31th 2020 Virtually to replace the canceled in-person meeting....

NOT TRADE FAIRS

Slope protection with Trinter

Vegetation is the best ally to protect slopes from erosion and design is key to provide a green, durable surface. TRINTER turf reinforcement mats...

NOT TRADE FAIRS

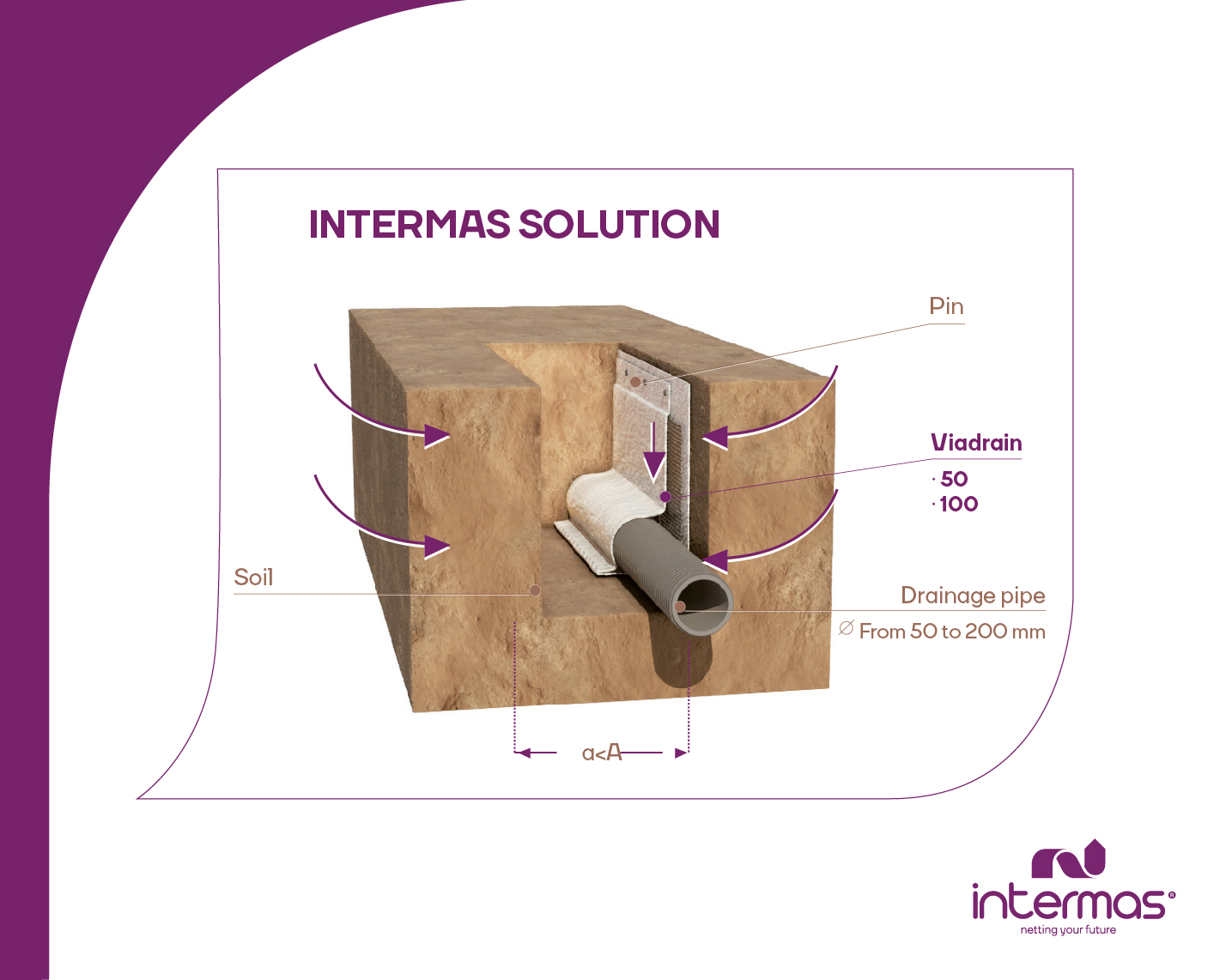

Anchor trench

Unlike granular materials, geocomposite drains can be installed on steep slopes following the pattern of the geomembrane. This setting protects the...

NOT TRADE FAIRS

Vertical drainage

Drainage geocomposites can be installed directly on concrete structures using a nail gun and do not require the use of imported soil. Intermas...

NOT TRADE FAIRS

In-trench drainage

Geocomposite drains are employed to substitute traditional in-trench drains. Unlike the conventional approach, geocomposites can be installed in...

27 May 2020 - 27 May 2020

NOT TRADE FAIRS

International Technical Webinar: IGS Chile & Intermas

Design of geocomposite drains for mining applications in situations of natural aggregates.

Roșia Montană, Romania

NOT TRADE FAIRS

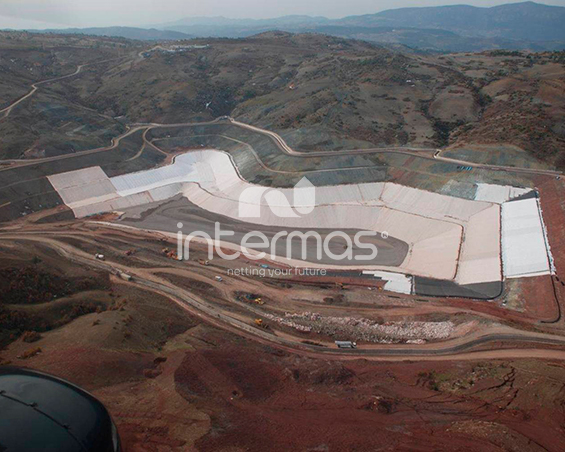

Rosia Montana's Gold Mine Capping Case Study

Rosia Montana has always been rich in mineral resources, especially in gold. Unfortunately the accident at Baia Mare in 2000 brought home to Romanians...

NOT TRADE FAIRS

#LaFuerzaDelPackaging

"When everything has stopped, our industry has stepped up to the plate so that the world can move forward", the motto of the social media campaign...

NOT TRADE FAIRS

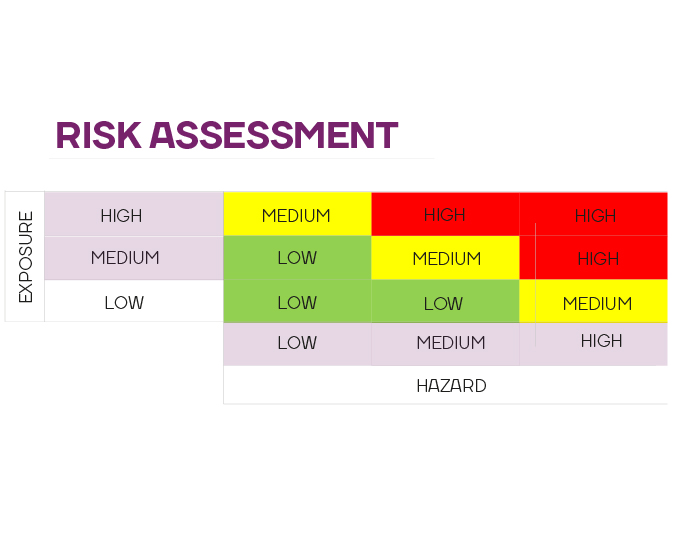

Risk assessment

Conventional drainage systems are mainly constituted of poorly graded granular materials.

NOT TRADE FAIRS

Physical clogging in leatchate drainage

Filtration in heap leaching is constantly affected by concentration of fine particles over the geotextile filter, which compromise the drainage...

NOT TRADE FAIRS

Un système de ventilation dans les bâtiments d'élevage

On parle de notre système brise-vent dans le Paysan Breton.

NOT TRADE FAIRS

CASE STUDY - LANDFILL ZAMÁRDI, HUNGARY

Intermas case study is from a project carried out in Zamárdi, Hungary. The works were carried out by Strabag on behalf of Nemzeti Infrastruktura...

NOT TRADE FAIRS

GEOCOMPOSITE DRAINS IN LANDFILLS

Drainage aggregates are voluminous materials which require huge amounts of material to shape conventional drainage layers. When applied to landfill...

NOT TRADE FAIRS

Installation efficiency

While conventional drainage systems are usually composed by large volumes of aggregates, geotextiles and pipelines forming a fishbone structure,...

Huesca, Spain

NOT TRADE FAIRS

A tree protection solution against the plague of rabbits

Intermas offers solutions to protect your culture production against rodents.

NOT TRADE FAIRS

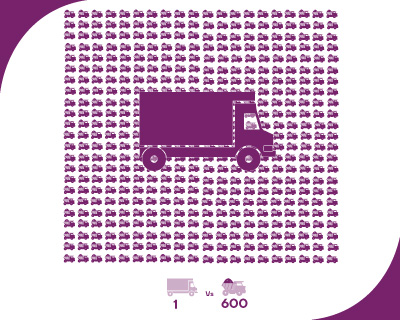

Supply Chain Management

In conventional designs, large volumes of aggregates are required to shape drainage layers, involving hundreds of transportation units per hectare....

NOT TRADE FAIRS

Drainage in buried structure

Some of the most common buried structures are affected by extreme compressive conditions.

27 Feb 2020 - 28 Feb 2020

Madrid

NOT TRADE FAIRS

Intermas and the importance of cooperation for sustainable and responsible development!

Thanks Cluster Manager Acuiplus to receive us last week in Madrid where our Intermas Business Manager of Aquaculture Activity gave a speech about our...

Worldwide

NOT TRADE FAIRS

World Wildlife Day 2020

Forests are home to nearly half of all land-based species. They provide the air we breathe and much of the resources to sustain the livelihoods of...

NOT TRADE FAIRS

Intermas® focuses on the environment

Intemas® offers new solutions to reduce the impact of plastic in the fishing industry (science of the exploitation of living aquatic resources). Read...

NOT TRADE FAIRS

Techdrain drainage geocomposite in phosphates containment site, India

In the efforts to attend the most demanding and technical markets, INTERMAS has proved its experience by supplying the drainage geocomposite layer of...

NOT TRADE FAIRS

Supply of drainage geocomposite CAPDRAIN at Hyderabad Municipal Solid Waste Dump Site Capping

During the 2019, INTERMAS NETS has been awarded with the winning tendering of its drainage geocomposites in the capping of Hyderabad Municipal Solid...

13 Nov 2019 - 13 Nov 2019

NOT TRADE FAIRS

TRELLISNET - Agricultural nets for fruit & vegetables growing

Trellisnet is an Intermas net to support climbing vegetables allowing them to grow taller and to encourage the uniform and straight growth of ...

21 Oct 2019

USA

NOT TRADE FAIRS

Professional Development

On September 15th and 16th, our area sales manager for the USA attended a two days training provided by INDA Association members.

21 Mar 2019 - 21 Mar 2019

NOT TRADE FAIRS

INTERMAS Runs Live

Intermas is a world leading company in the polymer-based and extruded plastic mesh market. For INTERMAS, the introduction of SAP ERP has been...

NOT TRADE FAIRS

INTERMAS INNOVATES AND LOUNCHES THE GA UNDERGROUND WARNING MESH EQUIPPED WITH THE ELIOT TECHNOLOGY

Intermas creates the GA warning mesh equiped with the ELIOT technology (Localization and Identification Equipment for Underground Conduit Systems)...